SSGC protocol comprises the following steps:

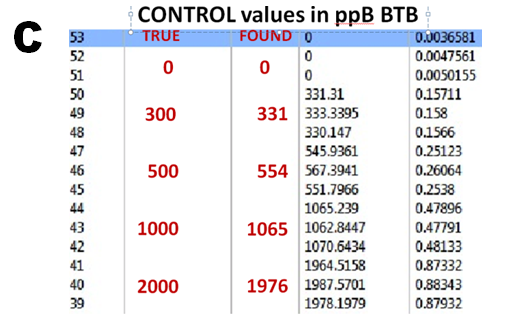

1) generate MASTER calibration by using a series of standard solutions, while setting data collection window at peak maxima (A).

2) Using the most concentrated standard, and MASTER calibration, measure the virtual concentrations in data collection windows, placed on the trailing edge of the peak (B).

3) Use the thus obtained concentrations and corresponding absorbancies to construct the SLAVE calibration.

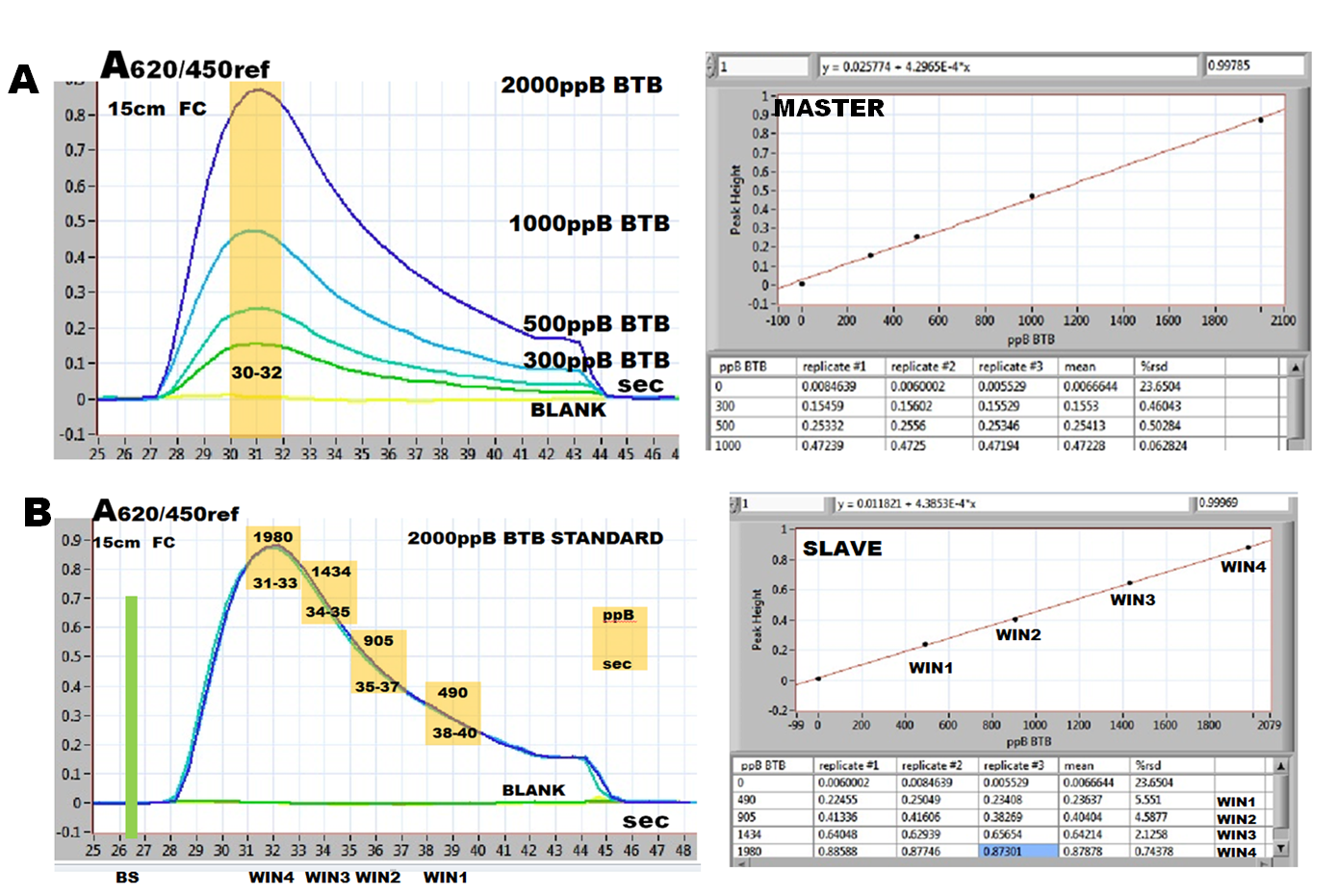

4) Verify SLAVE performance by analyzing the series of standard solutions by using SLAVE calibration graph with window set at the peak maximum (C). The experiments were performed using miniSIA-1 instrument, bromothymol blue dye (BTB) in ammonium chloride buffer (pH8, 5). This buffer was also used as a carrier and reagent solutions. The software protocol (D) outlined on the previous page, was used to control the system and to collect data in selected windows.

Single Standard Gradient Calibration

Feasibility Study Using Dye

2.2.38.B.

Results, summarized in control chart (C) confirm the feasibility of SSGC, and the reproducibility of the calibration in miniSI format. While this experiment did not include chemical reactions, it confirms that SSGC will be suitable to calibrate instruments like FAA, ICP or MS, when no chemical reactions are taking place when samples are introduced by the flow system.